Log Washer

Log Washer

>> Log Washer is ideal for scrubbing difficult materials such as tough insoluble

clays, conglomerates, soft stone and cemented aggregate

>> Oversize bearings and gears

>> Thick-walled shafts

>> Lower end bolted to fully machined stub shaft. Upper end mounted through

flexible coupling to output shaft of gearbox

>> The compound drive divides the operating load over an optimal combination

of oversized helical and spur gears

>> Continuous grinding and abrading log washer paddles

Description of Log washer

Log washer is used to wash ores with mud before the employment of mineral processing technology as well as increase ore dressing indexes

of back-end technology. They are often used to wash cores such as manganese ore, iron ore, limestone, tungsten ore, tin ore and silica sand

ore. According to silt content, grain size and washing difficulty level of cores, double-screw washer, troughed ore washer or cylindrical ore washer

can be selected. RXT log washer is apply to desliming of sand and gravel. Single-deck or double-deck round screen is installed inside the drum

of the washer which can get two or three types of sand and gravel production of different specifications.

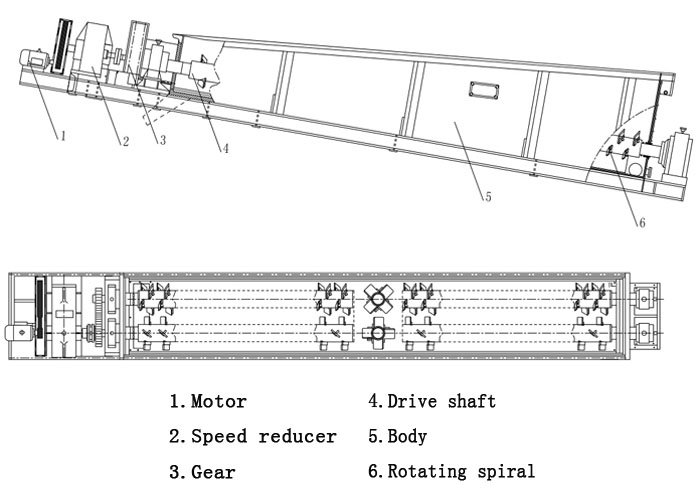

Structure of Log washer

Technical Specification of Log washer

|

Model |

Spiral Dia. (mm) |

Rotating Speed (r/min) |

Feeding size (mm) |

Tank slope (o) |

Output (t/h) |

Power (kw) |

Weight (t) |

|

2RXL320 |

Φ320×3200 |

28 |

≤30 |

≤12 |

10 |

4 |

0.9 |

|

2RXL400 |

Φ400×4600 |

23 |

≤30 |

≤12 |

20 |

5.5 |

1.9 |

|

2RXL540 |

Φ540×4600 |

23 |

≤30 |

≤12 |

25 |

7.5 |

3.9 |

|

2RXL750 |

Φ750×7600 |

22.7 |

≤70 |

≤12 |

50 |

15 |

17.2 |

|

2RXL800 |

Φ800×7600 |

22 |

≤70 |

≤12 |

70 |

18.5 |

18.9 |

|

2RXL914 |

Φ914×7600 |

21 |

≤70 |

≤12 |

100 |

22 |

23 |

Application of Log washer

Contact Us

|

Name: Helen Huang |

|

Skype: sabrina88196 |

|

|

Tel: 0086-15879777833 |

|

|

Email: helen@perrymining.com |

- Previous:Back

- Next:Rotary Scrubber